Transforming Commodity Management: Reclaiming Time and Millions with Research-Driven Tracking

Freeing engineers from spreadsheets to focus on what they do best

Engineers managing construction materials across multiple projects face decision fatigue when tracking hundreds of commodity codes while balancing budget constraints and timeline pressures. How do we reduce cognitive load in data-heavy workflows while maintaining accuracy?

Behavioral Challenge

Conducted workflow analysis and user interviews with engineers and procurement teams to understand mental models, pain points in spreadsheet-based systems, and decision-making patterns under time pressure.

Research Approach

Managing complex data sets, reducing manual entry errors, streamlining multi-stakeholder workflows- these are patterns that appear across industries from supply chain management to financial reconciliation.

Transferable Insights

The Goal: A digital transformation of Kiewit's commodity materials tracking system, replacing manual, error-prone processes with a streamlined, automated solution that tracks materials from order to invoice.

My Role: Lead UX Researcher—spearheading the deep dive into existing workflows, uncovering critical pain points, and facilitating a collaborative design process that directly informed the solution.

Key Outcome: Research-driven solution projected to save $4.9 million annually and free up to 10 hours per week per Project Engineer (29,625 hours saved company-wide annually)

Project Snapshot

Industry: Construction / Enterprise Resource Planning (ERP) / Financial Management

Challenge: Overcome manual, error-prone tracking of construction materials from order to invoice

Team: Lead UX Researcher (Me), Stakeholders (District & Project Engineers), Designer, Programmers, Project Manager, Product Owner

Constraints: Constant project restructuring, stakeholder delays, technical integration challenges, complex accounting requirements

The Solution

A Smarter Commodity Management System

Our solution leveraged modern technology to bypass manual inputs, creating a unified platform for comprehensive commodity management.

Goals:

Automate Data Capture: Eliminate manual entry of delivery tickets

Ensure Accuracy: Automatically verify tickets against orders and invoices, flagging discrepancies

Provide Robust Accounting: Accurately track complex accounting codes (WBSs) and multiple tax situations

Boost Productivity: Free up Project Engineers for higher-value tasks

Discovery: Understanding User Pain Points

Methodology: Conducted user interviews with 11 key participants, including District and Project Engineers—the primary users of the existing system.

Key Research Insights (3 Major Challenges):

1. Time-Consuming

Engineers spent nearly a full week setting up trackers for each project

10-20 hours weekly on manual ticket input

Time diverted from core engineering responsibilities

2. Error-Prone

Manual inputs were a significant source of errors

Lost physical tickets compounded accuracy issues

Vendors' reluctance to add data further complicated the process

3. Accounting Complexities

Existing systems struggled with multi-part accounting codes (Split WBSs)

Varied tax situations (e.g., non-taxable permanent materials) led to reconciliation issues

Visualizing Current Workflows: Process Mapping

Methodology: Developed a detailed process map visualizing the entire user journey from order placement to invoice approval.

Insight: The map clearly highlighted numerous manual handoffs, repetitive data entry, and potential error points in the existing process—making a compelling case for digitalization and serving as a critical tool for identifying specific areas for improvement..

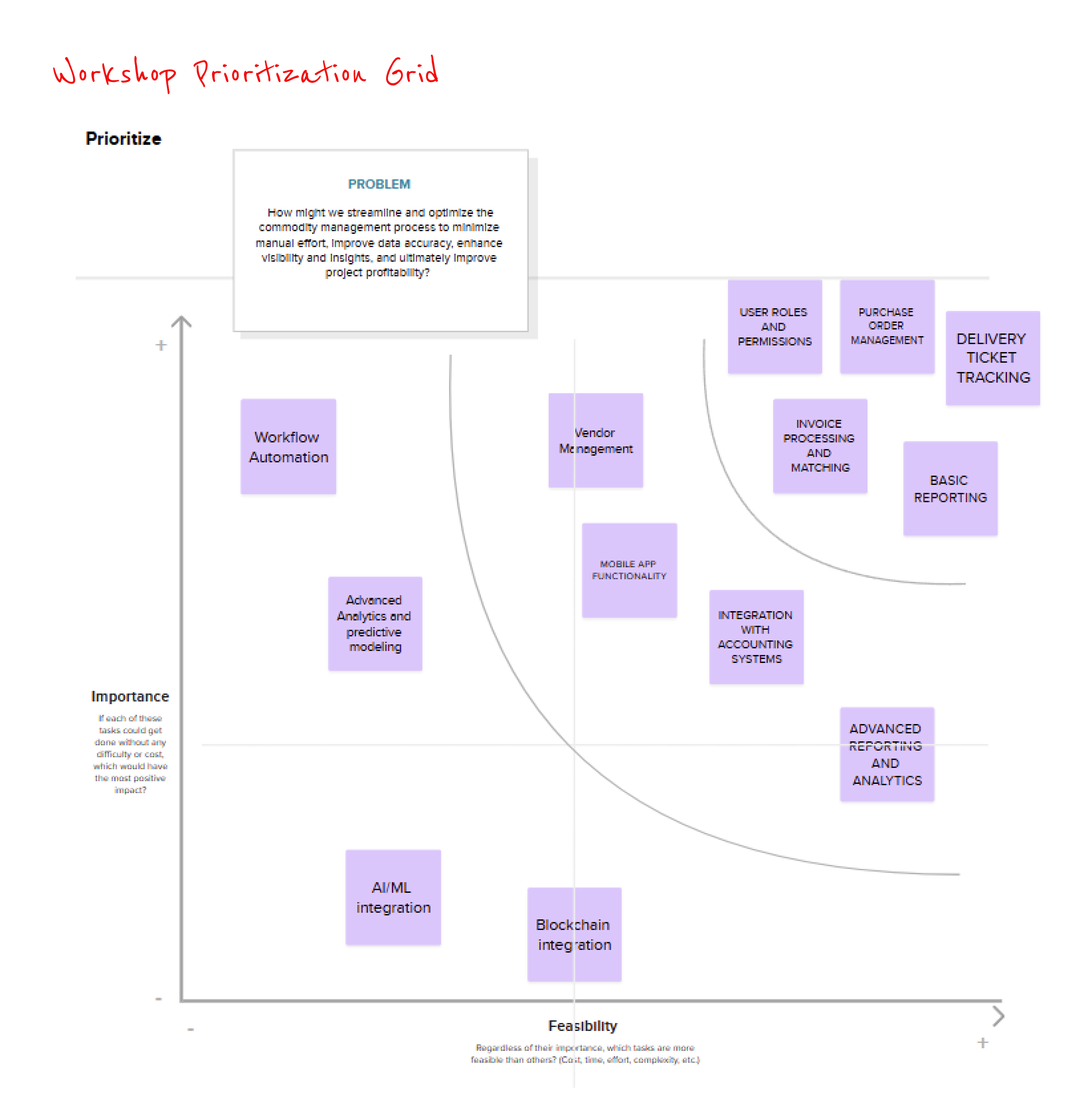

Building Consensus & Prioritizing: Requirements Workshop

Methodology: Facilitated a requirements workshop with key stakeholders, including District and Project Engineers and leadership.

Insight: This collaborative session was crucial for prioritizing features based on direct user needs and business objectives, and for securing essential stakeholder buy-in. The workshop refined the product vision, ensuring alignment and a clear path forward.

Key Insights Informing the Product Blueprint:

System Consolidation: A unified platform was necessary to streamline fragmented processes

Real-Time Visibility: Users needed instant access to material status and delivery timelines

Simplified Approvals: The existing approval workflow needed significant streamlining to reduce delays

Research Recommendations:

Leveraging Automation for Impact

Our research directly informed the integration of modern technology to address identified pain points and deliver significant efficiencies.

1. Automating Data Capture & Verification

OCR Scanning Technology

Implemented Optical Character Recognition (OCR) to digitize handwritten delivery tickets

Eliminated manual data entry—identified by users as a major time sink and error source

Automated Verification

System automatically compares delivery tickets against orders and invoices

Proactively notifies field engineers of discrepancies—a direct solution to the "error-prone" challenge

Discrepancies must be resolved before payment, ensuring financial accuracy

2. Robust Accounting & Reporting

Complex Accounting Handling

System engineered to robustly manage multiple cost centers (Split WBSs) and diverse tax codes

Addressed a critical challenge highlighted in user interviews that previous automated systems struggled with

Enhanced Reporting

Tracks orders, tickets, and invoices against contractual amounts

Provides robust reporting on inventory levels, accumulated costs, and remaining contract allotments

Enables more accurate forecasting and decision-making

“Lots of engineers don’t like doing that kind of work... they’ll get frustrated and want to do something else because they didn’t... go to school to be an admin and punch tickets and look at spreadsheets.”

Projected Impact

Note: Due to organizational restructuring, I was unable to see this project through to launch. The outcomes below represent projected savings based on our research findings and stakeholder validation.

Projected Annual Savings:

Total Cost Savings: $46.9 million annually through process automation and efficiency improvements

Overpayment Reduction: $45.9 million reduction in overpayments

Time Savings (Per Engineer): Up to 592.5 hours per year freed per Project Engineer for higher-value tasks

Time Savings (Company-Wide): 29,625 hours saved across the company annually

Research Metrics:

User Interviews: 11 participants to uncover deep pain points

Workshops: 1 requirements workshop to prioritize and align stakeholders

Key Learnings

This project highlighted the power of UX research to drive tangible business value in complex enterprise environments.

What I Learned:

Collaboration Drives Success: Facilitating workshops and securing stakeholder buy-in was crucial for consensus and project vision alignment

Technology as an Enabler: Leveraging tools like OCR and automation directly addressed core inefficiencies identified in research, leading to projected immense time and cost savings

Iteration is Essential: Addressing complex technical challenges (like diverse accounting requirements) reinforced the value of iterative research and design

Quantifying Impact: Seeing the projected financial and time savings underscored how streamlining processes, informed by user understanding, can lead to measurable, transformative organizational impact

Planned Next Steps

While organizational changes prevented me from seeing this project through to completion, the research foundation I established supported these planned enhancements:

Usability Testing: Evaluate system intuitiveness and identify areas for UX improvement

Field Observations: Observe users in their natural environment to uncover hidden inefficiencies

Expanded Automation: Explore further opportunities for automation, including third-party system integrations

Enhanced Analytics: Develop robust dashboards for actionable insights, forecasting, and decision-making

Scale & Training: Roll out the solution to more teams with comprehensive training for smooth adoption

This project demonstrated how aligning technology with deep user needs through rigorous research creates the foundation for measurable, impactful outcomes in enterprise environments.